PHOTOS, VIDEO and ARTICLE by ALBERTO DELLA BEFFA

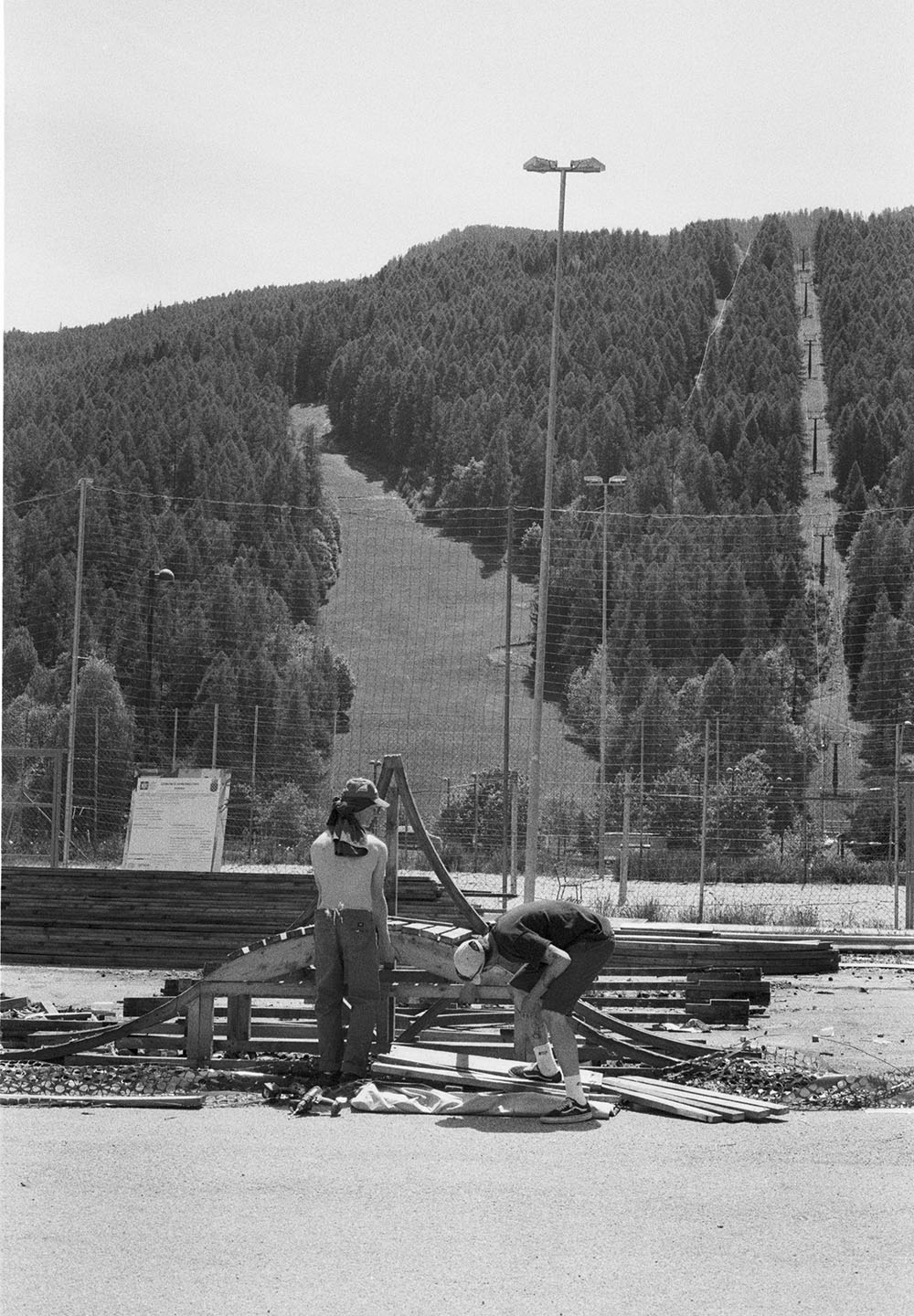

In June 2022, me and some friends heard that a city in the mountains one hour away from Turin was about to send their old wooden ramp to the landfill. The ramp was a spine mini ramp two meters high and eight meters wide. This ramp was only six years old but every winter it was getting a couple meters of snow on top and that snow was being left there until spring time every year. This led to the flat rotting a couple times and every time the city was spending a few thousand euros to fix it. And in 2022 they didn’t care anymore and just decided to throw it away, so we went and talked to a guy working in the city council and we got the deal to dismantle it and take the good material away. That material (something like 20,000€ worth of wood and solid surface panels) ended up in my backyard and waited there some months until I was free from work for a month.

In December 2023, the building of the Cinghial DIY was finished (at least the main bowl) and since then a lot of great skaters passed by and this video is a recap of all those crazy sessions. Filmed and edited by Alberto Della Beffa. Photos by Alberto Della Beffa and Fabrizio Martinena filmed between 2023 and 2025.

The design needed to change because the original shape was pretty boring and we wanted to build a smaller but wider mini bowl. So I sat with Pietro De la Pierre, a good friend of mine and an amazing skatepark designer, and considering the materials we had, we designed this heart shaped bowl. I only had to buy some wood to complete the flat and the decks, but 85% of the overall materials came from that old wooden ramp.

The main part of the building, the wooden straight mini ramp, took three weeks and then I kept on working on it every now and then in my free time. I finished the decks, the curved coping and then we tried this experimental way to pour a fill free corner and hip without using any wood underneath. To get some money for the concrete, we started a gofundme that went pretty well, a lot of friends from all over Europe put some money in and we were able to collect more than a 1000 euros, which was actually all we spent for this last phase. We poured some support columns and then a first rebar net which had on top a really thin net made for plaster walls. Then we continued by doing a thin plaster layer which then ended up being the box to pour the actual concrete inside. All the rebar job was welded to some metal plates attached to the wood transitions of the mini ramp to make it all well connected. The concrete is really thin but with cotton fibers in the mix that prevent it to crack even being 5-7 cm thick, and it’s been dyed in brown with pigments to make it look like a wood panel.

The whole construction took a year – all of my free time, but very little money. That means that we should all look out for those old ramps, laying around our cities, that often end up in landfills, while they could be recovered and refurbished for private use. Cinghial means “boar” in Piedmont local dialect and I picked that name because they are the real locals of the woods around the bowl.

Construction Photography

Backyard DIY t-shirt

Confusion Online Shop